Finish Name

Specification

Benefit

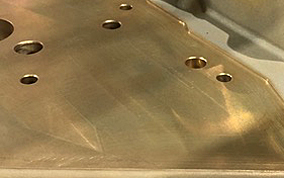

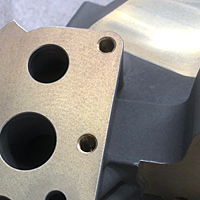

Chromate conversion coatings are also called chemical film coatings, or Alodine or Irridite (trade names) coatings. They produce a very thin protective coating. Used mainly on aluminum or aluminum alloys, chemical conversion coating provides a protective layer against corrosion and can be used as a primer for paint. Extra benefits accrue when the coating is sealed. This coating can be used for protection at the same time when low electrical resistance is needed.

Erie Plating provides both hexavalent and trivalent chromate conversion. Trivalent chromate conversion coatings are nontoxic, RoHS-compliant, Nadcap-certified alternative to hexavalent chromate conversion coatings.

Suitable for

Industry use

Base metal substrate

Effect

Accreditations

Features of Chemical Conversion Coating:

- Provides corrosion resistance on aluminum sheet, extrusions, forgings and aluminum sand or die-castings.

- Inexpensive in all applications.

- When specified, provides nearly zero electrical resistance.

- Excellent base for paint; paint base

- Prolongs shelf life and resists staining and fingerprinting.

- Provides super corrosion resistance on all aluminum products by addition of seal.

- Excellent corrosion protection.

- Salt spray hours from 72 to 120 depending on the part and alloy.