Finish Name

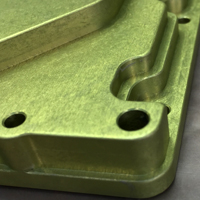

Chromic Acid Anodizing - Type I

Anodizing on Aluminum

Anodizing, Chromic Type I

Aluminum Chromic Anodizing

USG Anodizing

Specialized Chromic Acid Anodize Type I

Specification

MIL-A-8625 Type I

Other

Benefit

Type I Chromic Acid Anodizing passes an electrical flow (anodizing) through a chromic acid solution. This creates a thin aluminum oxide film that is non-reactive, a good primer base, and corrosion-resistant. This is a favored coating for parts undergoing high-stress, such as in the aerospace industry.

Suitable for

Paint and prime base

Welded Components and Assemblies

Industry use

Aerospace

Military and Defense

Industrial

Automotive

Flight Critical

Various

Base metal substrate

Aluminum

Aluminum Alloys

2024 Aluminum Alloy

6062 Aluminum Alloy

7075 Aluminum Alloy

Effect

Critical Corrosion Protection

Seal Options

Dichromate

Sodium dichromate

Hot Water

Nickel Acetate

Duplex seal

Accreditations

Nadcap

Features:

- For aluminum with copper content below 5%.

- Thin but has greater abrasion resistant surface than bare aluminum. (Thicknesses range from .00005" to .0001".)

- Very corrosion resistant coating for the small thickness.

- Provides an exceptional base for primers, bonding agents, and organic coatings.

- Provides nonreactive surface for metal-to-metal contact interfaces such as welded or riveted assemblies.

- Provides nonreactive surface for metal-to-elastomer contact interfaces

Note: We provide Chromic Anodizing Type I, Sulfuric Anodizing with Color - Type II, and Sulfuric Anodizing - Type II.